Selecting the perfect roll forming partner is a critical decision that can significantly impact the success of your project. By considering the right factors, you can ensure a productive collaboration, exceptional product quality, and seamless communication. In this blog, we provide a comprehensive checklist of the top 7 critical success factors for choosing the ideal roll forming partner who aligns with your unique requirements.

1. Industry Expertise and Experience

Experience and expertise in your industry are the cornerstones of a successful roll forming partnership. A company well-versed in the intricacies of your sector will offer valuable insights and provide tailored solutions, addressing your project’s specific requirements. When assessing potential partners, consider their history and portfolio within your industry, as well as client testimonials and case studies that showcase successful collaborations.

2. Design, Engineering, and Production Capabilities

The roll forming partner’s design, engineering, and production capabilities significantly impact the custom components’ quality and performance. Investigate the company’s design and engineering experience, focusing on their ability to work with various materials, shapes, and profiles. Collaborating with a partner that demonstrates proficiency in CAD design, tooling, and material selection ensures your project’s successful execution.

3. Quality Assurance and Control

A strong quality assurance program is vital, as it guarantees the custom roll formed components adhere to stringent performance standards and meet your project’s specific needs. When selecting a roll forming partner, inquire about their quality control measures, certifications, and policies, such as ISO 9001.

4. Customer Service and Communication

Effective communication and a commitment to customer satisfaction are critical drivers of a successful roll forming partnership. The ideal partner demonstrates attentiveness to your project requirements, provides timely and comprehensive responses to inquiries, and offers ongoing support and guidance throughout the collaboration.

5. Cost Efficiency and Pricing Structure

Cost efficiency is a vital factor in choosing a roll forming partner, with implications for your project’s bottom line. Assess the company’s pricing structure in terms of material costs, tooling costs, labor charges, and shipping expenses, as well as any additional value-added services they provide.

6. Flexibility and Adaptability

The ability to adapt to changing project requirements and market demands is essential in a roll forming partnership. When assessing potential partners, pay close attention to their capacity for flexibility and scalability, including their ability to accommodate short lead times, adjust production volumes, and modify designs as needed.

7. Logistic Efficiency and Supply Chain Management

Your roll forming partner’s logistic efficiency and supply chain management capabilities significantly influence the timeliness of component deliveries. It is crucial to select a partner with efficient shipping services, consistent lead times, and inventory management solutions.

By thoroughly evaluating each potential roll forming partner against these seven critical success factors, you can cultivate a productive and successful collaboration that meets your project’s unique needs. Choose a partner with field expertise, design and production capabilities, quality assurance, strong customer service, cost efficiency, flexibility, and exceptional supply chain management to ensure your project’s precision and success.

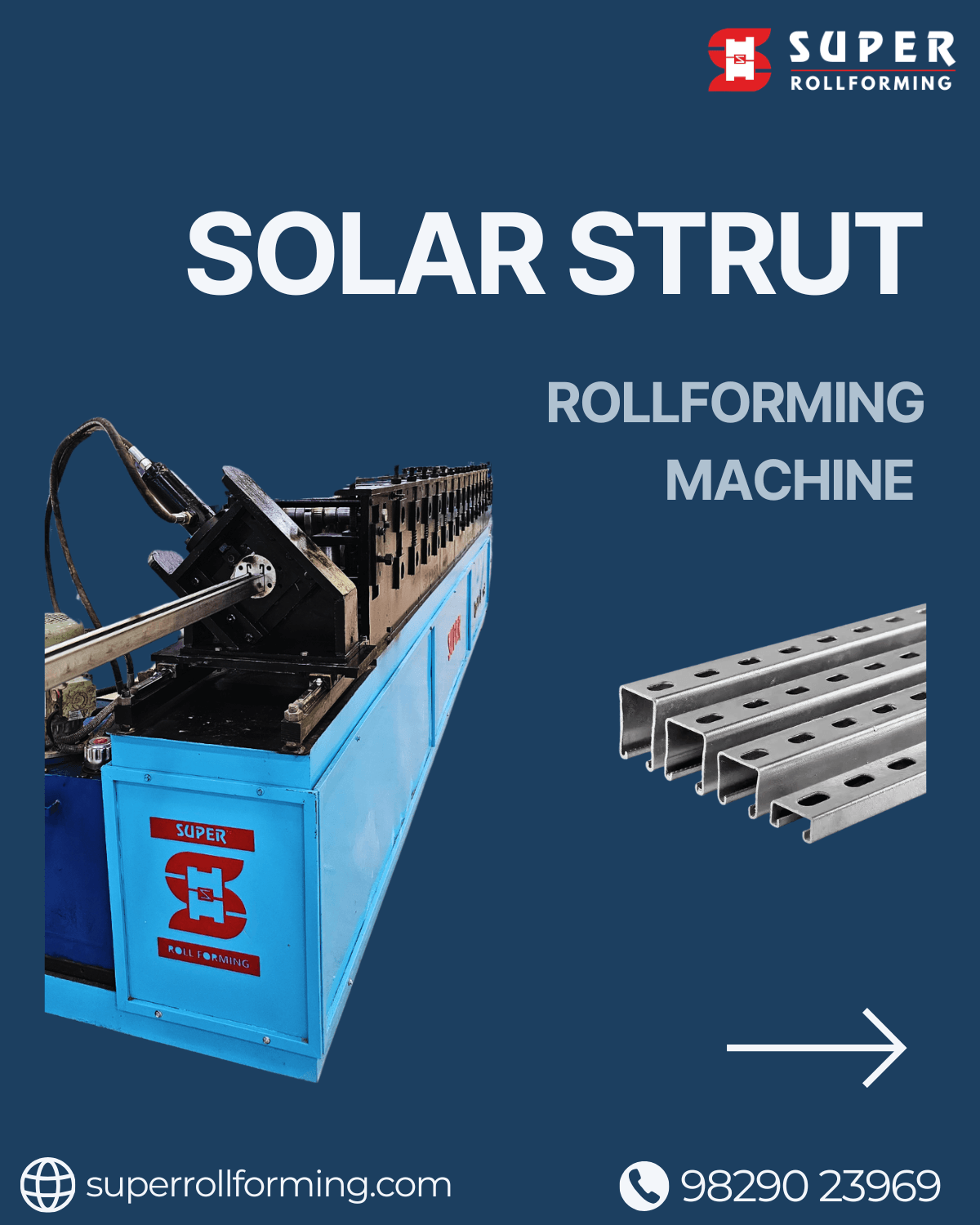

Why Choose Super Rollforming?

Super Rollforming’s commitment to industry expertise, design and production capabilities, quality assurance, excellent customer service, cost efficiency, flexibility, and supply chain proficiency makes us an outstanding choice for your next roll forming endeavor. Our expert team is dedicated to guiding you through the entire process, guaranteeing exceptional custom roll formed components through our custom metal fabrication services.