Choose the Right Roll Forming Machine to stay competitive in 2026’s rapidly evolving manufacturing landscape. Automation, precision engineering, smart production systems, and energy efficiency are no longer optional — they are essential. If your company operates in metal fabrication, construction materials, roofing systems, automotive components, or structural steel production, investing in the right equipment can determine your long-term profitability.

One of the most critical decisions manufacturers face today is How to Choose the Right Roll Forming Machine for their specific operations. The wrong investment can lead to production delays, inconsistent quality, higher maintenance costs, and reduced ROI. The right machine, however, becomes a powerful growth engine for your business.

How to Choose the Right Roll Forming Machine Today

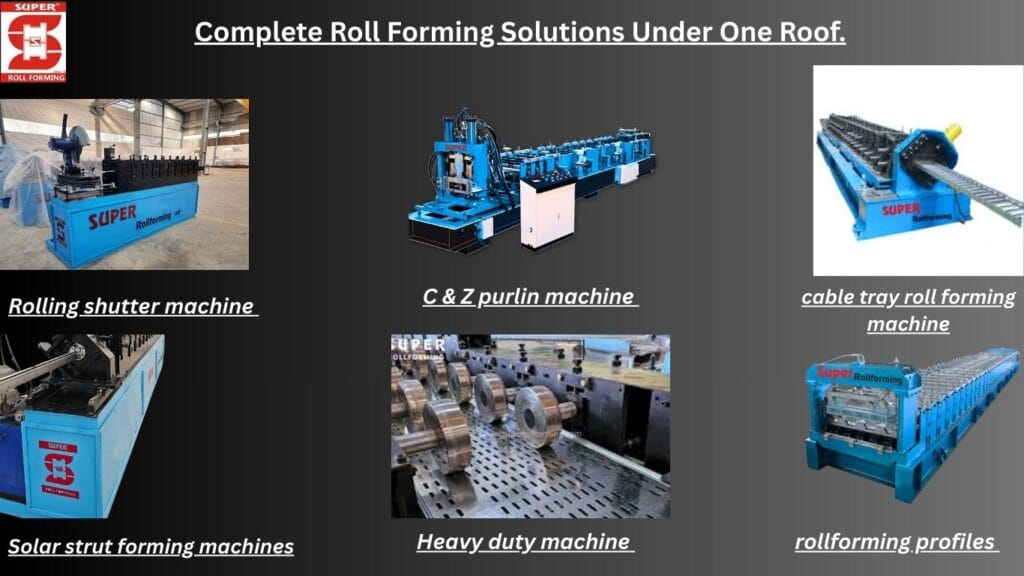

A roll forming machine is a high-efficiency metal forming system designed to bend continuous strips of metal into specific profiles through sequential roller stations. It is widely used in:

- Roofing sheet manufacturing

- Purlin production

- Door frame fabrication

- Cable tray systems

- Solar mounting structures

- Industrial racking systems

- Automotive structural components

Before deciding How to Choose the Right Roll Forming Machine, it is important to understand your product profile requirements, material type (GI, PPGI, aluminum, stainless steel), and production capacity.

Modern roll forming machines in 2026 are integrated with:

- PLC control systems

- Servo motors

- Automatic stacking systems

- High-speed hydraulic cutting

- Smart diagnostics and IoT monitoring

Define Your Production Requirements Clearly

The first and most important step in understanding How to Choose the Right Roll Forming Machine is analyzing your production needs.

Ask yourself:

- What profile do you need to produce?

- What thickness range will you handle?

- What is your daily or monthly output target?

- Do you need a single profile or multi-profile capability?

- Is customization required?

For example, a roofing sheet manufacturer may require high-speed production with minimal downtime, while a structural purlin producer may prioritize heavy-duty performance and thickness flexibility.

Super Rollforming offers tailored solutions designed specifically for different industries, ensuring your machine matches your business model.

Choose the Right Roll Forming Machine: Configuration & Design

When considering the Right Roll Forming Machine, machine configuration is critical.

Important design factors include:

1. Number of Roller Stations

More roller stations allow smoother forming and better dimensional accuracy.

2. Shaft Diameter

Larger shaft diameters improve strength and durability.

3. Frame Structure

A heavy-duty frame ensures vibration control and longer machine life.

4. Drive System

Gearbox-driven systems provide better torque and durability compared to chain-driven systems.

A poorly built machine can cause profile distortion, edge cracking, and premature roller wear.

Choosing a manufacturer like Super Rollforming ensures precision-engineered components and long-term reliability.

Consider Automation and Smart Technology

In 2026, automation is no longer a luxury — it is a necessity.

If you are researching How to Choose the Right Roll Forming Machine, focus on machines that include:

- PLC-based control systems

- Touchscreen interface

- Automatic length control

- Error detection systems

- Remote monitoring capabilities

- Servo-driven punching systems

Smart automation reduces human error, increases consistency, and boosts production efficiency.

Super Rollforming integrates intelligent control systems that enhance operational productivity while minimizing downtime.

Material Compatibility

Not all roll forming machines are built for the same materials. Understanding material compatibility is essential when deciding How to Choose the Right Roll Forming Machine.

Consider:

- Coil width range

- Material thickness range

- Yield strength handling capacity

- Surface coating protection

If your machine cannot handle high-tensile steel or thicker gauges, you may face frequent breakdowns and inconsistent output.

A reputable supplier like Super Rollforming ensures machines are designed with precise load-bearing capacity and roller hardness suited for different metals.

Customization & Flexibility

Market demand changes rapidly. Today’s roofing profile might not be tomorrow’s best seller.

When evaluating How to Choose the Right Roll Forming Machine, flexibility is a major competitive advantage.

Look for:

- Quick-change cassette systems

- Adjustable roller stations

- Multi-profile compatibility

- Expandable punching options

A flexible machine allows you to adapt without purchasing entirely new equipment.

Super Rollforming provides customized roll forming lines that grow with your business.

Maintaining Quality at High Production Speeds

Speed matters — but not at the cost of accuracy.

When researching How to Choose the Right Roll Forming Machine, compare:

- Maximum line speed

- Cutting accuracy

- Tolerance control

- Surface finish quality

High-speed machines without stability may cause dimensional errors. Precision matters especially in structural and automotive components.

Investing in a powerful yet precision-engineered solution from Super Rollforming ensures high output without compromising product quality.

Maintenance & After-Sales Support

Many businesses overlook this factor when deciding How to Choose the Right Roll Forming Machine, but after-sales service is crucial.

Consider:

- Availability of spare parts

- Technical training support

- Remote troubleshooting

- Warranty coverage

- Service response time

Downtime equals financial loss.

Partnering with Super Rollforming ensures long-term technical support and reliable service infrastructure.

Investment Value and Profitability

Price should not be your only deciding factor.

When determining How to Choose the Right Roll Forming Machine, focus on:

- Energy efficiency

- Maintenance cost

- Production capacity

- Long-term durability

- Scrap reduction

A low-cost machine may initially seem attractive but could cost significantly more in repairs and production inefficiency.

Choosing a high-quality machine from Super Rollforming ensures better ROI and sustainable growth.

Compliance & Safety Standards

Modern manufacturing requires strict compliance with safety and quality standards.

Ensure the machine includes:

- Emergency stop systems

- Safety guards

- CE or ISO certifications

- Electrical safety compliance

Safety protects both workers and your company reputation.

Why Choose Super Rollforming in 2026?

Selecting the right manufacturer is as important as choosing the machine itself.

Super Rollforming delivers:

- Custom-engineered roll forming solutions

- Advanced automation integration

- Heavy-duty machine construction

- Industry-specific customization

- Reliable after-sales support

- Competitive pricing

Their commitment to quality and innovation makes them a preferred choice for businesses looking to scale in 2026.

FAQs

1. How to Choose the Right Roll Forming Machine for my business?

Focus on production capacity, material thickness range, automation features, customization options, and long-term ROI.

2. Why is automation important in 2026 roll forming machines?

Automation improves speed, accuracy, and reduces labor costs, making production more efficient.

3. Can one machine produce different profiles?

Yes, modern machines offer adjustable roller systems and quick-change setups for multiple profiles.

4. What materials can a roll forming machine process?

Most machines handle GI, PPGI, aluminum, stainless steel, and high-tensile steel.

5. How important is after-sales support?

Very important. Reliable support ensures minimal downtime and long-term performance.

Conclusion

Understanding How to Choose the Right Roll Forming Machine requires careful planning, technical evaluation, and long-term thinking. In 2026, businesses that invest in automation, flexibility, and durability will dominate the manufacturing landscape.

By defining your production needs, evaluating machine specifications, considering automation, and partnering with a trusted manufacturer like Super Rollforming, you can make a confident investment that drives profitability and operational excellence.